Steam Pipeline Work

Steam Pipeline Work Specification

- Pressure Rating

- Up to 25 Bar

- Type

- Steam Pipeline Work

- Material

- Stainless Steel / Mild Steel / Carbon Steel

- Service Location

- On Site

- Insulation Material

- Glass Wool / Mineral Wool / Calcium Silicate

- Installation Method

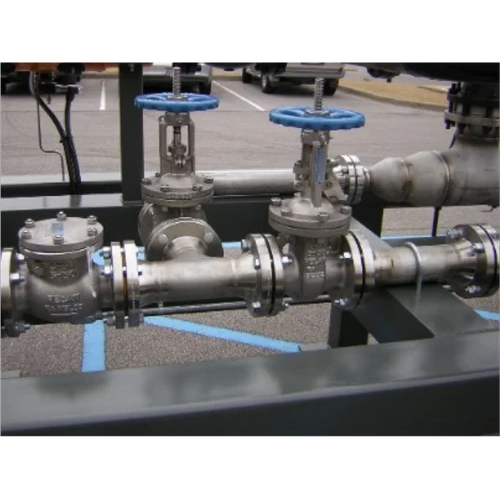

- Welding / Flanged / Threaded Joints

- Maintenance

- Periodic Inspection Recommended

- Application Area

- Refineries, Power Plants, Chemical Industries, Food Processing Units

- Fittings

- Flanges, Elbows, Tees, Reducers, Valves

- Leak Test

- Hydro Testing & Pneumatic Testing available

- Usage/Application

- Industrial Steam Distribution

- Design Standards

- ASME B31.1, IBR Standards

- Pipe Size Range

- 1/2 inch - 24 inch

- Corrosion Protection

- Anti-Corrosion Coating on Request

- Surface Treatment

- Galvanized / Painted / Insulated

- Temperature Range

- Up to 600°C

Steam Pipeline Work Trade Information

- Minimum Order Quantity

- 120 Square Foots

- Supply Ability

- 1000 Square Foots Per Month

- Delivery Time

- 7 Days

About Steam Pipeline Work

Select Steam Pipeline Work offers an unrivaled solution for industrial steam distribution across refineries, power plants, and food processing units. Designed to elite standards like ASME B31.1 and IBR, our celebrated pipelines are available in stainless steel, mild steel, and carbon steel, with options for galvanized, painted, or insulated surfaces. Featuring remarkable leak tests-hydro or pneumatic-and corrosion protection upon request, we deliver installations using welding, flanged, or threaded joints. Experience periodic inspections for lasting performance. Deal with us for a trusted exporter, manufacturer, supplier, and service provider across India.

Site Applications and Industrial Usage of Steam Pipeline Work

Steam Pipeline Work is expertly used for distributing steam in a variety of sites such as refineries, power plants, chemical industries, and food processing units. Recognized for its type as heavy-duty industrial pipeline work, it facilitates safe and efficient steam transfer across sectors. The system typically services on-site applications, supporting core industrial operations that demand high temperature and pressure reliability in their daily usage. This ensures seamless operation in demanding environments.

Sample Policy, Delivery, and Payment Terms for Steam Pipeline Work

Our Steam Pipeline Work sample policy ensures transparency-clients can request samples at the list price before confirming their order. Quick drop-off schedules help us maintain competitive lead times, ensuring lowest price delivery without compromising quality. Payments are flexible and can be arranged to suit project scope and client requirements, providing customers ease throughout the process. With a focus on responsiveness, each order is managed for timely delivery and optimal value.

Site Applications and Industrial Usage of Steam Pipeline Work

Steam Pipeline Work is expertly used for distributing steam in a variety of sites such as refineries, power plants, chemical industries, and food processing units. Recognized for its type as heavy-duty industrial pipeline work, it facilitates safe and efficient steam transfer across sectors. The system typically services on-site applications, supporting core industrial operations that demand high temperature and pressure reliability in their daily usage. This ensures seamless operation in demanding environments.

Sample Policy, Delivery, and Payment Terms for Steam Pipeline Work

Our Steam Pipeline Work sample policy ensures transparency-clients can request samples at the list price before confirming their order. Quick drop-off schedules help us maintain competitive lead times, ensuring lowest price delivery without compromising quality. Payments are flexible and can be arranged to suit project scope and client requirements, providing customers ease throughout the process. With a focus on responsiveness, each order is managed for timely delivery and optimal value.

FAQ's of Steam Pipeline Work:

Q: How is leak testing performed on your steam pipeline systems?

A: Leak testing is conducted through hydro testing and pneumatic testing to ensure each pipeline section is robust and secure. These tests verify that the system operates safely under the specified pressure ratings.Q: What materials are used for the construction of the pipelines?

A: We offer steam pipelines crafted from stainless steel, mild steel, or carbon steel, providing options to match specific application requirements and enhance durability in varied industrial settings.Q: Where can your Steam Pipeline Work be installed?

A: Our elite pipeline solutions are suitable for on-site installation in refineries, power plants, chemical industries, and food processing units across India.Q: What joints and fittings are supported with your pipeline installations?

A: Installations can be executed using welding, flanged, or threaded joints. The fitting options include flanges, elbows, tees, reducers, and valves for comprehensive project adaptability.Q: What is the recommended maintenance process for the steam pipelines?

A: We recommend regular periodic inspection of the pipelines to maintain performance and ensure safe operation over their lifetime, complying with industry best practices.Q: What are the benefits of adding insulation and corrosion protection to the pipelines?

A: Insulation materials like glass wool, mineral wool, or calcium silicate help in temperature retention and energy efficiency, while anti-corrosion coatings on request prolong pipeline lifespan and reliability.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Send Inquiry

Send Inquiry Send SMS

Send SMS English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese